From the idea to the delivery ...

Do you have an idea for a new product and are looking for the suitable material?

Thanks to our many years of experience in project work with our customers, we can accompany you safely, quickly and in a target-oriented way through the entire development process until the delivery of the first sheet.

Our extensively and modernly equipped R&D department with its own in-house test laboratory, technical centre and colour laboratory can propose and subsequently realise a material composite with defined design and reliable properties from a single source.

Of course we will be at your side to provide you with competent advice afterwards.

1. Your idea - our product proposal

⇒ Competent advice and support from our sales team

- clarification of the general requirements with regard to the end application (e.g. physical, mechanical, chemical, thermal)

- definition of the product design in terms of surface, colour and gloss

- coordination of the project schedule and negotiation of the purchasing and delivery conditions

2. Start of project development at MITRAS Materials

⇒ Cross-departmental delevopment work based on the requirement profile

- selection of the right raw material and definition of the material structure by the development department

- colour, gloss and design coordination by our colour laboratory and development department

- feasibility testing on the production line by the production and development departments

3. Implementation of colour and design

⇒ Colour matching of the desired colour by our in-house colour laboratory

- selection from our colour archive with over 6,000 own coulor developments

- colour matching based on a RAL or Pantone colour chart

- recipe setting according to any customer sample (e.g. metal, plastic, paper, etc ...)

4. MITRAS colour laboratory series

⇒ Extrusion of a laboratory sample in our technical center

- small sheet sample to judge the colouring and the design for the first orientation for the serial production

5. Planning and execution of sampling production / pre-series

⇒ Approval of the laboratory sample and of the sampling production / pre-series by the customer

⇒ Planning and organisation of the production process

- ensuring the availability of raw materials

- production of the colour masterbatch

⇒ Execution of the sampling production / pre-series

- determination of the process parameters by our production

- verification of the defined specifications by our quality team

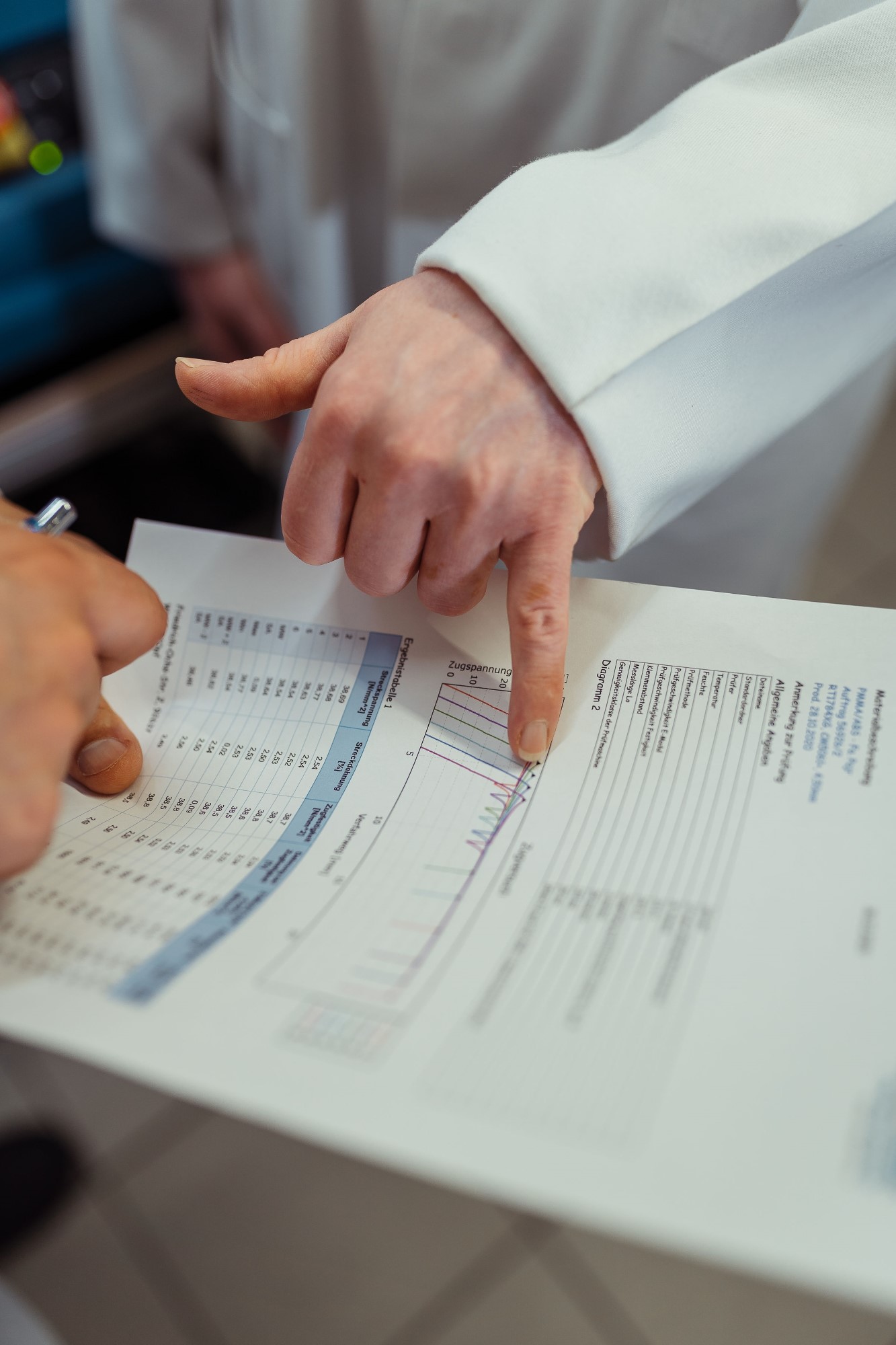

6. Approval process by the customer

⇒ Assesment of the sampling sheets

- carrying out thermoforming tests, processing

- evaluation of the final colouring, design, etc.

⇒ Feedback to us and product approval

⇒ Upon request: defintion of reference samples with regard to colour, gloss and surface quality

⇒ By agreement: measurement of furthervalues in MITRAS' own test laboratory

- e.g. colour, mechanical values, UV tests, fire tests, etc.

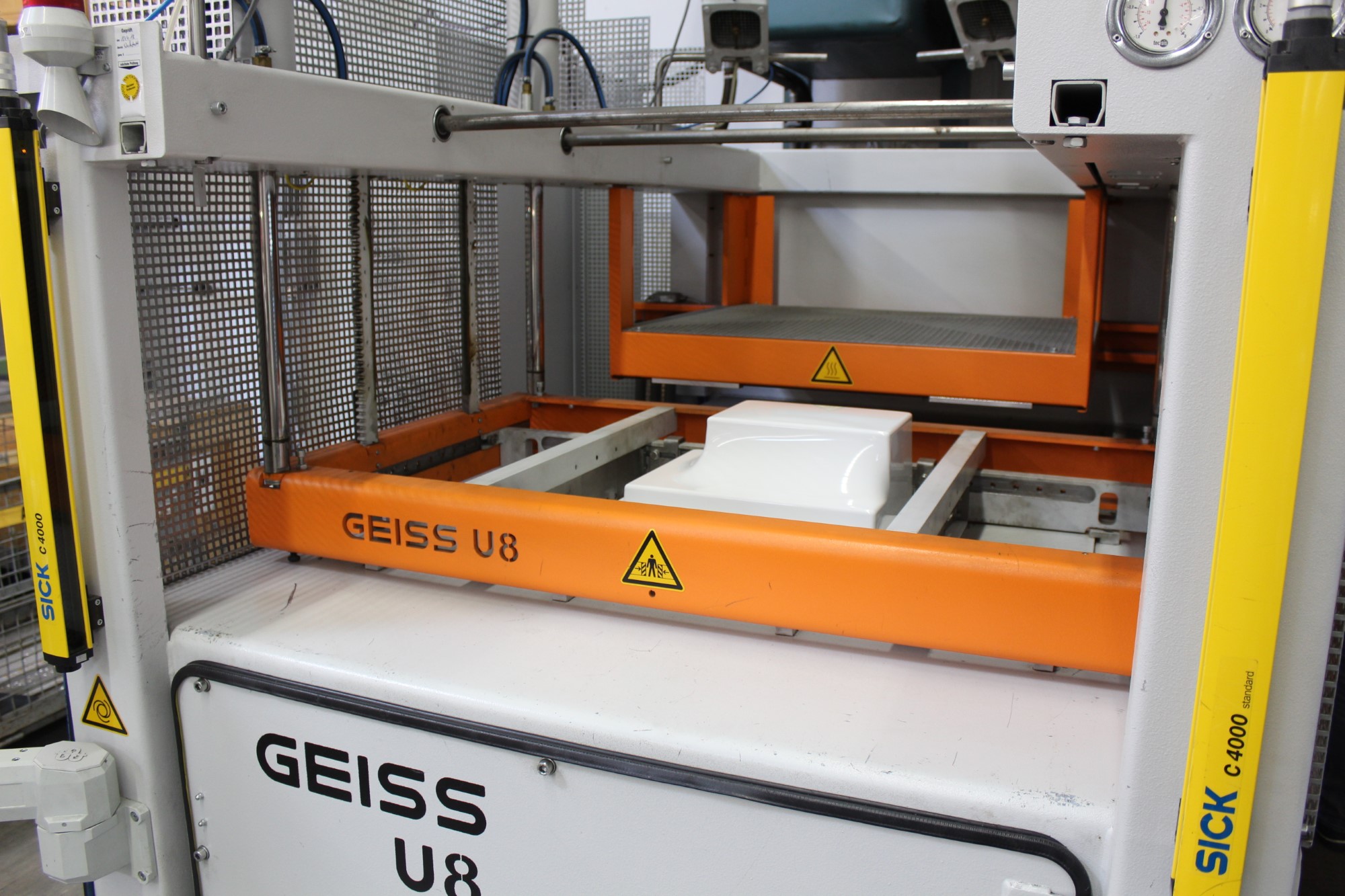

7. Customer approval: thermoforming and further processing steps

⇒ production of thermoformable sheets

⇒ delivery of the finished product